Classification of arcing during sputtering And avoidance

2021.10.11During the sputtering coating process, will appear Arc phenomenon, which is essentially be a low-voltage, high-current discharge process. One arc is a defect, and too much defects will affect product quality. Therefore, during the coating process, the occurrence of arcing must be strictly controlled.

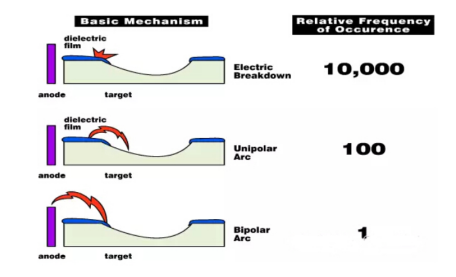

In the sputtering process, arcing can be divided into three categories:

The first type is high-voltage breakdown discharge,The high-voltage breakdown on the top and bottom metal surfaces of the cathode surface, which is caused by the loose structure of the cathode surface insulating layer.

The second type is called micro-arc discharge. The sputtering on the surface of the cathode is non-uniform, and only the atoms at the "track" are sputtered. The surface of the track is pure metal,A non-conductive insulating layer is deposited on the surface of the cathode outside the racetrack,On the surface of the insulating layer due to the attraction of the cathode potential,Accumulate a considerable amount of positively charged ions,After the accumulated positively charged ions reach a certain number, they will directly form an arc discharge with the exposed metal surface. The magnitude of the discharge current depends on the accumulated charge. It will not cause burn damage, but the visible red spots jump on the target. This phenomenon is particularly prominent during the compound sputtering process.

The third type is called inter-electrode discharge, which is the direct discharge between the anode and the exposed metal surface of the target surface, which can directly cause destructive burning. The control of this type of discharge mainly depends on the design of the mechanical structure of the target.

The probability of the occurrence of these three forms of discharge is: 10000:100:1. As shown below:

Reasonable target design can avoid inter-electrode discharge (the third type), so the key to high-stability operation is to eliminate the charge accumulation on the surface of the insulating layer. The DC pulse power supply can effectively achieve this purpose and avoid the occurrence of the other two types of arcing. In the DC pulse power supply, negative pulses are used for sputtering, and positive pulses are used to release accumulated charges. The average voltage of the negative pulse is 500-600V, the average voltage of the positive pulse is 60-80V, and the ratio of the positive pulse width to the negative pulse width of the sputtering is between 1:4 and 1:8.

< 上一篇

没有了!

下一篇 >

没有了!