Car parts

PVD coating has excellent wear resistance, low friction and corrosion resistance, which can effectively reduce the fuel consumption of the engine and reduce the friction of the sliding parts of the engine.

At the same time, the excellent dry lubrication performance ensures that the friction pair can work normally and stably while the lubricant is reduced, which greatly improve the lubrication performance and durability of parts and components,And On the premise of quality assurance to help customer to reduce costs and reduce consumption!

Main applications: oil needle, plunger, tappet, roller pin, piston pin, piston ring, valve seat, etc.

Coating Type | Coating Color | Coating thickness(um) | Coating Hardness(HV) | Max application temperature(°C) | Friction coefficient | Aplication area |

|---|---|---|---|---|---|---|

CrN | silvery white | 2-5 | 1800-2200 | 600 | 0.1-0.15 | High impact fatigue wear |

| SDC | Black | 1-4 | 2200-2400 | 300 | 0.1 | Reduce friction and wear resistance, suitable for high wear parts |

| TAC | Black | 0.2-1 | 4000-7000 | 450 | 0.05-0.15 | High hardness and high wear resistance, suitable for parts in harsh environments such as high pressure, high corrosion and high load |

| TiN | golden | 2-5 | 2000-2400 | 600 | 0.1-0.3 | Suitable for general wear-resistant environment |

Piston Pin

Piston Ring

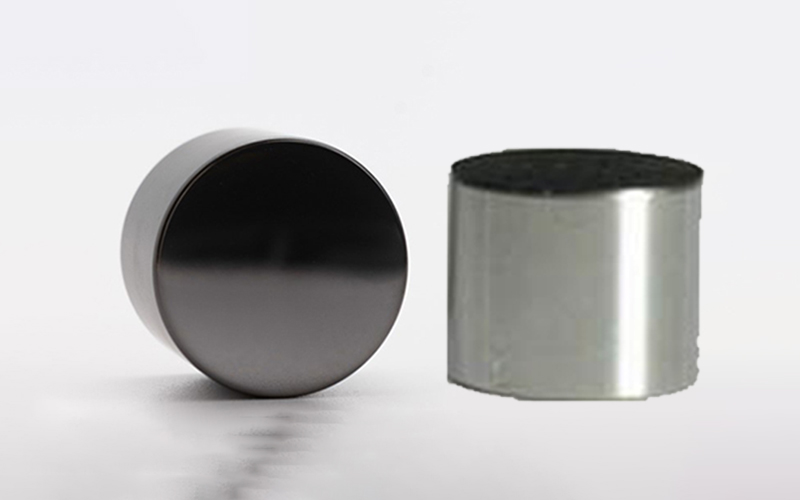

Tappet

Oil Needle

Plunger

Valve Stem

Ball Head

Control Valve

Roller Pin

Cam