Coating introduction

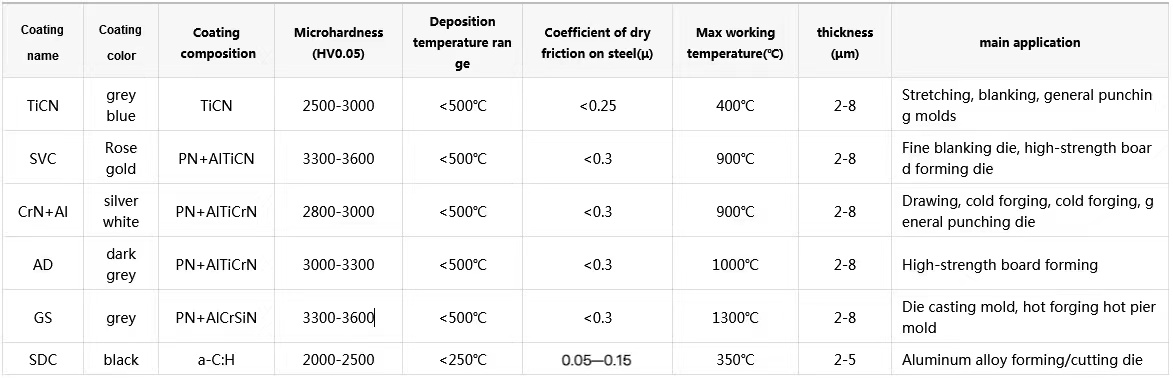

PVD coating can provide molds with high hardness, high wear resistance, low friction coefficient, high chemical stability and other characteristics, and is widely used in stamping molds, die-casting molds, injection molds and other industries.

Sude coating unique PVD technology

Duplex composite coating

Ordinary PVD coating has a fatal deficiency.

Although the hardness is high HV3000, the thickness is only 3 ~ 8μm, and it adheres to the mold substrate with hardness HV600-700. Similar to a thin layer of ice on a lake, although the ice surface is hard, once it is stressed, it will break because the lake is too soft. SUDE called it is "thin ice effect."

In order to eliminate the thin ice effect, Sude Coating has developed the DUPLEX PVD coating technology. First, the mold substrate is subjected to PN plasma nitriding treatment to form a nitride layer of up to 50-200μm on the surface. The hardness ranges from HV1200 to HV1200. The HV700 decreases gradually, which greatly improves the load-bearing capacity of the mold base itself.

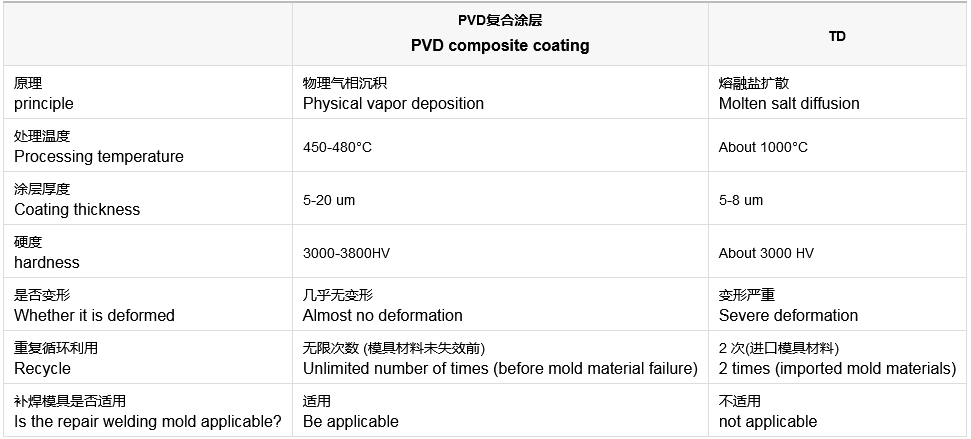

Comparison of PVD composite coating and TD